Product Description

1. Product Show

Single carriage with three systems computerized flat knitting machine with one high roller (36",52", 60", 66") or two rollers(72", 80") , without comb device. uses digital technology to machine knit Transfer, Tuck, Pointelle, Intarsia, Jacquard, Apparent Shape, Hidden Shape, and other regular or irregular patterns. This machine would be mostly used to automatically knit woolen sweaters. It can fit silk, cotton, woolen, terylene, mix-textile etc to the material.

2.

1)Main Technology Parameters:

A. Gauge: 3gg, 5gg, 7gg, 10gg, 12gg, 14gg, 16gg

B. Knitting width: 36 / 52 / 60 / 66 / 72 /80 inches

C. Knitting speed: Controlled by servo motor with 32 sections speed optional, max speed reach 1.2m/s. Servo motor uses the precise back award control and links up the high speed operation ability of digital signal processor (DSP), which controls IGBT to produce accurate output of electric current.

D. Knitting system: Single carriage with three systems

E. Knitting function: Transfer, tuck, pointell, intarsia, jacquard, evident shape, concealed shape and other regular or irregular patterns.

F. Needle board shift: Controlled by servo motor shift within 2 inches and with accurate adjusting function.

G. Detect alarm system: The safety alarm detect device has up-down and left-right swing functions which surmounts the normal flat knitting machine and great increases the detect protect function.

H. Encoder: Advanced coder equipped.

I. Transfer function: Triangle composite design can transfer needles from front to back and back to front together.

2)Production Process:

Production processing ----> Machine Adjusting ----> Packaging and Transportation

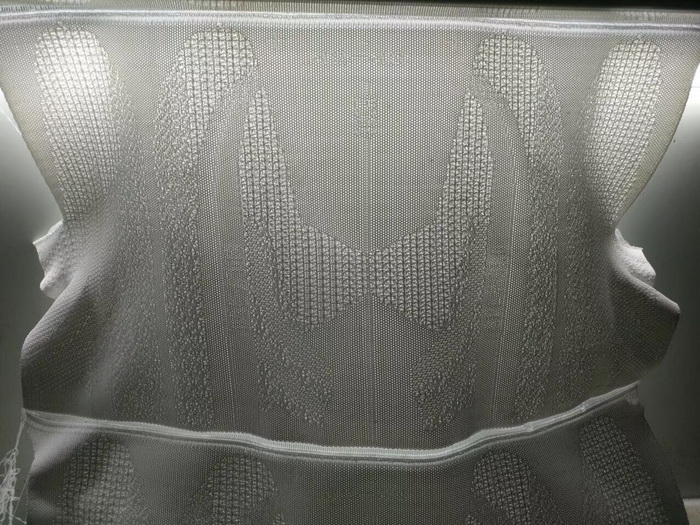

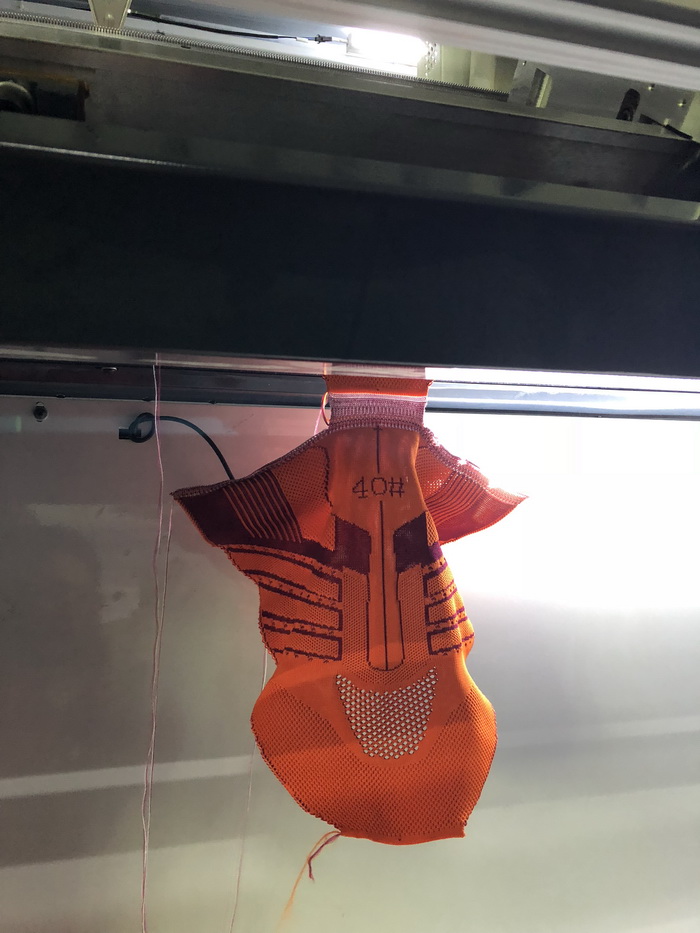

3. Knitwear Pattern Show:

Basic patterns like Plain Stitch, Rib Fabric, Links-and-Links, Interlock Stitch. Fancy patterns like Tuck Stitch, Jacquard, Eyelet Stitch, Aran, Cable, Racked Stitch, Plush Stitch, Pile Stitch, Cord Weave, Bright Narrowing and Enlarging Stitch.

|

Gauge: |

3gg, 5gg, 7gg, 10gg, 12gg, 14gg, 16gg |

|

Knitting range: |

36 / 52 / 60 / 66 / 72 / 80 inches |

|

Knitting speed: |

Spindle motor combines with rigid feedback control and with high-speed digital signal processor.(DSP) |

|

Operating system: |

single carriage with three systems |

|

Knitting system: |

Knitting transfer, Tuck, Pointelle, Intarsia, Jacquard, Chiaroscuro Narrowing and other regular / irregular knitting. |

|

Knit transfer. |

Triangle compound design, individual system can process knitting transfer , tuck. non-knitting to ensure high efficiency. |

|

Loop density: |

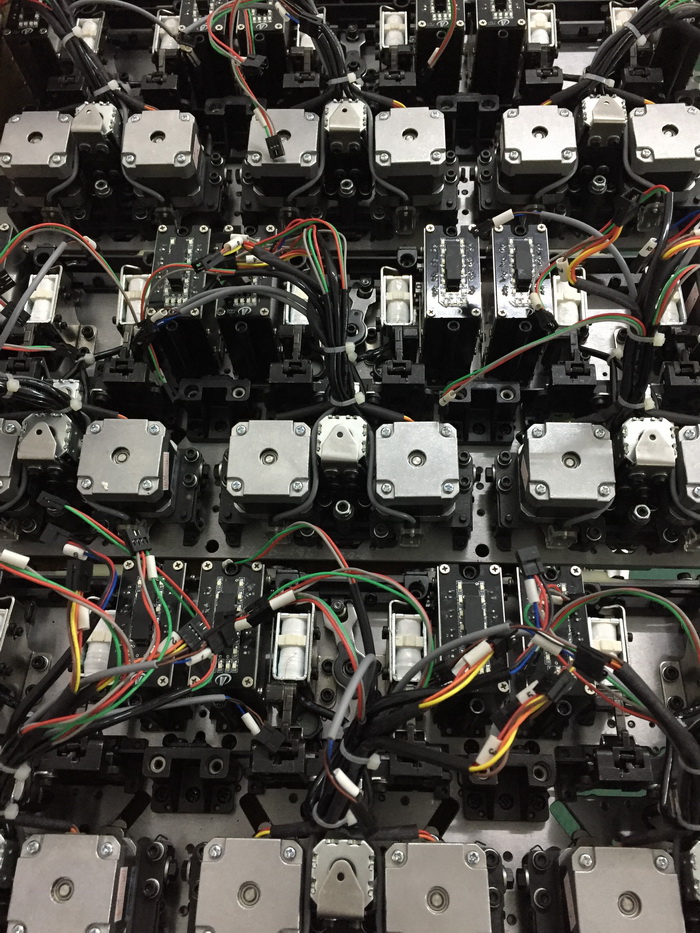

Controlled by stepping motor,32-levels of 0~650 density is adjustable to ensure the required quality. |

|

Sinker system: |

Controlled by stepping motor, adjust as per different cloth to reach the effect of narrowing and widening in knitting. |

|

Cloth wind-up: |

Computer program instruction, controlled by stepping motor, 32-level pull selection, adjustable range:0~100 |

|

Color-changing system: |

2 x 8 group yarn carriers are on the left & right sides of 4 guide rails. Shift yarn carrier can be placed at any position on the needle bed. |

|

Protection system: |

When yarn breaks, knot, yarns up, reverse rolls, shock act or when there is a program error an alarm will automatically activate. |

|

Controlling system: |

1) LCD displayer: Transferring graphics through USB and internet. The memory of USB Disk is 8G that can save a lot of files simultaneously and ensures that it can comply with the request freely.

2) Monitoring of picture: It shows different parameters by shifting Chinese and English. It is easy to operate and adjust the running machine.

3) Plate making system and controlling system (section of software) is easy to be observe, understand and upgrade. |

|

Power supply: |

Single phase:220V; Triple phase:380V |

|

Dimension: |

36": length x width x height : 2350 x 955 x 2010 mm ;

52": length x width x height : 3070 x 940 x 2010 mm ;

60": length x width x height : 3170 x 940 x 2010 mm ;

72": length x width x height : 3400 x 940 x 2010 mm ; |

|

Net weight: |

Approx.0.6 ~ 1.3 Metric Ton |